Tare da fitowar wayoyi masu wayo da na'urorin lantarki masu sawa, abubuwan da ake buƙata na hankali, bakin ciki, da ƙarancin ƙima sun zama al'ada, kuma masana'antun sun ƙara tsanantawa tare da samar da buƙatun allunan PCB a cikin waɗannan samfuran lantarki. Domin samun ingantacciyar hanyar sarrafa bayanan ingancin samfur, tsarin gano bayanai kamar etching haruffa, lambobin barcode, da lambobin QR akan allunan PCB sun fito kamar yadda lokutan ke buƙata.

Menene PCB?

PCB takaitaccen bayani ne na Hukumar da'ira ta Buga, wanda ke da jigilar wutar lantarki don kayan aikin lantarki da kayan lantarki.

Ana ƙara amfani da PCBs a cikin wayoyin hannu, kwamfutoci, kayan lantarki, motoci, da jirgin sama. Yanayin sarrafa al'ada yakan shafi aikin PCB zuwa digiri daban-daban, ko haifar da damuwa, ƙura da sauran ƙananan ƙwayoyin cuta masu cutarwa yayin sarrafawa ko haifar da tsayayyen wutar lantarki don yin tasiri ga aikin da'irar da aka buga. Sabanin haka, saboda hanyar sarrafawar da ba ta sadarwa ba, Laser PCB etching baya haifar da ƙananan barbashi masu cutarwa da wutar lantarki a tsaye, don haka ya yi fice a cikin yawancin hanyoyin sarrafawa na allon PCB, kuma manyan masana'antun PCB suna samun fifiko.

Menene Laser Marking Machine?

Alamar Laser ta zama hanyar sarrafawa mai mahimmanci a masana'antar zamani, musamman a fannonin injunan injina da kuma micromachining. Alamar Laser hanya ce ta etching wacce ke amfani da Laser mai ƙarfi mai ƙarfi don haskaka wani yanki na kayan aikin don yin vaporize ko canza launin kayan saman, don haka yana barin alamar dindindin.

Injin laser na iya tsara haruffa daban-daban, alamomi da alamu, kuma girman halayen zai iya zama daga millimeters zuwa micrometers, wanda ke da mahimmanci na musamman don hana jabun samfuran. Matsakaicin saurin haske mai kyau na Laser da aka mayar da hankali kamar kayan aiki ne, wanda zai iya cire kayan da ke saman abin da maki. Halinsa na ci gaba shine cewa tsarin etching ba aiki ne na sadarwa ba, wanda ba ya haifar da extrusion na inji ko damuwa na inji, don haka ba zai lalata kayan da aka sarrafa ba. Bugu da ƙari, saboda girman mayar da hankali na laser yana da ƙananan, yankin da zafi ya shafa yana da ƙananan, kuma aiki yana da kyau, wasu matakai waɗanda ba za a iya cimma su ta hanyar al'ada ba za a iya kammala su.

Injunan alamar PCB na Laser na al'ada gabaɗaya ba su da aikin gano matsayin kayan aikin, kuma suna amfani da kayan aiki don cimma matsayi, wato, sa baki da sakawa na hannu. Koyaya, yana da matukar wahala a cimma madaidaicin matsayi lokacin da aka ƙera kaya masu kyau ko ƙanƙanta, kuma yana da wahala a ɗauka da sanya kayan sarrafa. Baya ga abubuwan ɗan adam, yana da wahala a tabbatar da daidaito da daidaiton matsayi na zane a cikin ainihin aiki. jima'i. Matsayin sarrafa samfurin ta hanyar daidaiton na'urar zai shafi daidaitaccen matsayi na etching kai tsaye na sassan, kuma matsayin daidaitawar kowane abu na musamman na musamman. A lokaci guda, tasirin sarrafa abubuwan da ke ƙasa da matakin milimita ba za a iya bambanta da ido tsirara ba, kuma ana buƙatar tsarin ganowa mai zaman kansa don ganowa, kuma sa hannun hannu da matsayi yana da wahala, matakin sarrafa kansa yana da ƙasa, kuma daidaito yana da wahala a tabbatar da inganci yadda ya kamata.

STYLECNC da kansa ya ɓullo da hangen nesa galvanometer don magance gazawar fasahar data kasance. An shigar da tsarin hangen nesa a cikin galvanometer, don haka galvanometer yana da ayyuka na ganewa da sauri, matsayi mai dacewa, shirye-shiryen gani, da etching iri ɗaya, wanda ya sa aikin laser ya fi sauƙi, mafi dacewa kuma mafi dacewa. Gabatar da kyamarori na masana'antu da sakawa ta atomatik da kuma tsarin da aka sakawa fitarwa daidai yake da ƙara nau'in "ido" zuwa ga galvanometer na gani na gargajiya, wanda ke sa tsarin alamar Laser gabaɗaya ya fi dacewa da inganci, da adana ƙimar aiki mai yawa. Kuskuren da aikin hannu ya haifar yana raguwa, kuma ana iya kunna shi kyauta a wurare na musamman daban-daban.

Nau'in Laser PCB Etching Machines Nawa?

STYLECNCNa'urar etching Laser na PCB na iya zana lambobi masu girma ɗaya, lambobin girma biyu, haruffa, alamu tare da Laser fiber, CO2 Laser, ko UV Laser. Ana iya haɗa shi da layin samar da abokin ciniki don samar da kan layi, ana iya daidaita shi tare da na'ura mai ɗaukar nauyi da saukewa don samar da layi, kuma yana iya daidaita nisa ta atomatik don dacewa da nau'ikan allunan PCB. Production, ta hanyar CCD sakawa, atomatik tabbaci na kwarzana code ta barcode gun karatu, za a iya haɗa tare da abokin ciniki ta MES tsarin, da fasaha sigogi na kayan aiki ne yafi dogara a kan PCB masana'antu misali SMEMA misali.

An haɗa kayan aikin kai tsaye zuwa layin samarwa na PCB, kuma ana iya shigar da su a cikin ci gaba bayan haɓaka (bugu, ɗaukar hoto, haɓakawa, alamar tashi, bayan yin burodi) ko wasu wurare, galibi don alamar haruffa. Kayan aiki yana ɗaukar hanyar yin alama ta tashi, kwamitin PCB yana gudana cikin kayan aiki ta hanyar layin taro, kuma yana fitowa daga kayan aiki bayan alamar tashi.

Fiber Laser Engraving Machines

Nawa ne Kudin Laser PCB Etching Machine?

Lokacin da kuke buƙatar injin PCB Laser, kuna iya mamakin yadda ake farawa. Akwai 'yan abubuwa da za a yi la'akari da su ciki har da nau'in Laser, ikon Laser, software, da girman tebur. Abu na 1st mafi yawan masu siye suna so su sani shine abin da injunan zane-zanen Laser PCB yawanci tsada. The fiber Laser PCB alama inji aka saka farashi daga $2,980.00 ku $8,780.00, da CO2 Laser PCB engraving inji yana da farashin kewayon daga $4,500.00 ku $9,800.00. UV Laser PCB etching inji farashin daga $6,600.00 zuwa $12,700.00.

Yadda za a Laser Etch PCB Board?

Amfani da na'urar etching laser na PCB shima yana da sauƙi, kuma ana iya sarrafa shi bayan horo mai sauƙi. Akwai galibin matakai guda 5 masu zuwa.

Mataki 1. Kunnawa

1.1. Tabbatar cewa wayar ƙasa na kayan aiki tana ƙasa.

1.2. Bincika ko igiyar wutar lantarki na na'ura mai alamar Laser tana da alaƙa da kyau kuma abin dogaro.

1.3. Saka maɓallin maɓalli, kunna shi 90 digiri a agogon hannu zuwa matsayin "kunna", kunna babban wutar lantarki, kuma hasken wutar lantarki yana kunne.

1.4. Tabbatar da cewa canjin tasha na gaggawa na na'ura mai alamar Laser yana cikin matsi.

1.5. Kunna wutar lantarki na mai masaukin kwamfuta da mai saka idanu na kwamfuta.

1.6. Juyawa jajayen tasha tasha gaggawa ta hanyar kibiya don sa ta tashi, sannan ana iya kunna kan Laser, kuma kan laser zai fara sama bayan kamar minti 1.

1.7. Cire murfin ruwan tabarau; a wannan lokacin, ana kunna na'urar yin alama ta Laser, kuma tana iya karɓar umarnin mai aiki don aiwatar da aikin alamar.

Mataki 2. PCB Etching

2.1. Danna icon sau biyu na software na etching na PCB don shigar da shirin.

2.2. Zaɓi fayil ɗin da za a sassaƙa, danna kwanan wata da lokaci sau biyu a cikin abun cikin don gyarawa, sannan danna Ok don kammala gyaran.

Mataki na 3. Gwaji da Matsayi

3.1. A kan tebur ko layin samarwa, sanya yanki na gwaji daidai da h8 na PCB da za a zana shi, kuma tabbatar da cewa ɓangaren gwajin ya tabbata.

3.2. Fara aiki ta aiki da PCB software sarrafa kwamfuta.

Mataki 4. Daidaita Mayar da hankali

4.1. Daidaita sigogi kamar ƙarfi da saurin sassaƙawa a cikin software mai alama.

4.2. Shigar da software, danna kwanan wata da aka zana sau biyu, ja sama da ƙasa tare da linzamin kwamfuta, kuma daidaita matsayin sassaƙa zuwa wurin da ya dace.

4.3. Bayan kammala matakan da ke sama, ana iya yin gwajin etching na PCB.

4.4. Bayan gwajin yayi daidai, sake kunna allon PCB.

Mataki na 5. Kashe

5.1. Danna maballin jan naman kaza (maɓallin dakatar da gaggawa) don yanke ikon kan Laser.

5.2. Bayan tabbatar da cewa IPC ba ta gudanar da kowace software, fita kuma a rufe kullum.

5.3. Juya maɓalli na maɓalli 90 a kissan agogo baya zuwa wurin "kashe", kashe babban wutar lantarki, kuma hasken wutar lantarki yana kashe.

5.4. Cire maɓallin kuma ajiye shi don amfani na gaba.

5.5. Rufe hular ruwan tabarau.

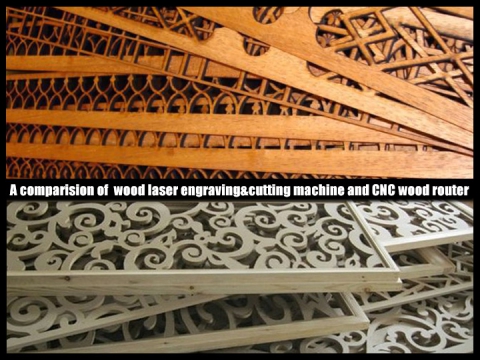

Laser Marking VS Silk Printing

Tsarin bugu na allo na gargajiya yana amfani da allon hoton da aka shirya, kuma ana amfani da matsa lamba na waje don sanya tawada halin shiga ta wasu ragar allon, kuma ya ɓace a saman allon kewayawa. Za a toshe sauran ragamar da ke kan allon, kuma tawada ba za ta shiga ba, sai an samu guraben da ke saman allon. Bace tawada zai samar da rubutu, tambura, alamu, da dai sauransu Wannan aiki hanya ne in mun gwada da cheap da sauri, amma yana da disadvantages na m engraving sakamako, sauki fadowa kashe na markings, rashin iyawa ga etch PCB allon tare da kananan format, da kuma wasu guba na sinadaran albarkatun kasa.

Alamar Laser tana amfani da Laser mai ƙarfi mai ƙarfi don ɓata allon PCB a cikin gida don vapori ko canza launin saman kayan, ta haka yana barin alamar dindindin. Wannan aikin da ba na tuntuɓar sadarwa ba zai iya zana lambar QR bayyananne akan ƙaramin tsari, yana tabbatar da daidaito da inganci. A lokaci guda, alamar laser ba za a sawa ba saboda matsanancin zafi da ƙananan zafin jiki, canje-canjen acid-base da rikice-rikice na waje, kuma baya buƙatar taimakon sinadaran, kuma ba shi da wani mummunan tasiri a kan lafiyar ma'aikata da muhalli.

PCB Laser alama inji yana da mafi daidaito da sassauci, wanda zai iya gyara ga shortcomings na siliki allo bugu, ƙwarai inganta samar da inganci da yawan amfanin ƙasa, rage farashin da rage gurbatawa. A halin yanzu, an yi amfani da shi sosai a fagage da yawa kamar samfuran dijital, na'urori masu sawa, da allunan kewayar motoci.

Laser Marking VS Buga Inkjet

A cikin farkon kwanakin, bayanai kamar kirtani, hotuna, bayanin lamba, da lambobin QR a saman PCB an gano su ta tawada. Tare da ci gaban thinning da miniaturization na lantarki kayan aiki, da nisa na PCB hukumar ne sosai kananan. Domin adana amfanin sararin samaniya, a ƙarƙashin yanayi na al'ada, lambar QR da aka yiwa alama akan allon PCB ƙanƙanta ce, tare da girma da ƙarami. Ana iya samun alamar lambobin QR ta hanyar fasahar yin alama ta Laser.

Idan aka kwatanta da hanyar inkjet, fasahar alamar Laser ta fi dacewa da muhalli da tattalin arziki, alamar dindindin ba za a iya gogewa cikin sauƙi ba, zane-zanen da ba a tuntuɓar ba zai lalata substrate, daidaiton aiki yana da girma, rayuwar sabis ɗin yana da tsayi, da aiki da inganci yana da sauri, da Laser engraving yana da daɗi, babu wata dabara a bayyane lokacin da hannu ya taɓa shi, aikin da hannu yana da sauƙi, kuma aiki mai kama da wawa.

Summary

An haɗa sabon ƙarni na etching PCB tare da fasahar laser. Fasahar yin alama ta Laser tana taimaka wa masana'antar hukumar PCB don kammala cikakkiyar kulawar inganci. Babban kasuwar PCB yana ba da sararin ci gaba mai fa'ida don masana'antar yin alama ta Laser.