Tare da ci gaban masana'antun masana'antu na duniya don haɓakawa, hankali, da gyare-gyare, an yi amfani da laser a cikin masana'antun masana'antu, biomedical, soja da sauran fannoni saboda kyakkyawar monochromaticity, shugabanci, haske da sauran halaye. Sarkar masana'antu ta duniya. Yayin da rabon aiki a cikin masana'antar laser ya ci gaba da girma, aikace-aikacen kewayon laser a cikin micromachining ya zama mafi girma. A cikin rayuwar yau da kullun, ana iya ganin micromachining laser a ko'ina. Bugu da ƙari, ana iya ganin fasahar micromachining laser a ko'ina a cikin alamar samfurin lantarki, alamar shinge na lantarki, alamar kwanan watan samar da abinci da magunguna, micromachining na mabukaci, yankan da walda na shingen ƙarfe na wayar hannu. Bugu da kari, ana kuma amfani da injin Laser a cikin yankan allon PCB/FPCB da gunkin allo, naushin yumbu da rubutu, gilashi, sapphire, yankan wafer da ƙaramin naushi.

Bari Mu Sani Manyan Hanyoyi 6 na Laser Micromachining.

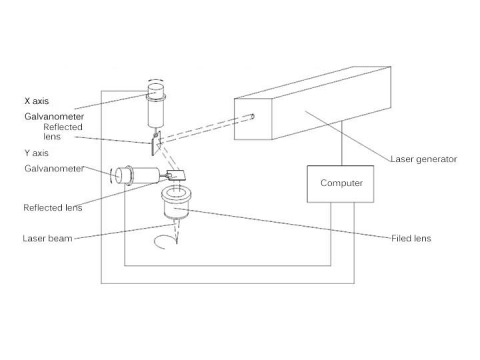

Laser micromachining shine aikace-aikacen masana'antu na fasahar Laser. Yana mai da hankali ga wani takamaiman ƙarfin Laser akan abin da aka sarrafa ta yadda Laser ɗin ke hulɗa da abu don zafi, narke ko vaporize kayan sarrafawa don cimma manufar sarrafawa. Nau'in na'ura ce ta Laser Beam machining (LBM). A halin yanzu, Laser micromachining aikace-aikace a cikin Laser masana'antu, yafi hada Laser sabon, Laser marking, Laser waldi, Laser engraving, Laser surface jiyya, da Laser. 3D bugu.

Yankan Laser

Ƙa'ida: Yi amfani da katako mai ƙarfi mai ƙarfi mai ƙarfi na Laser don haskaka kayan aikin don narke da sauri, tururi, cirewa ko isa wurin kunna wuta na kayan da ba a so. A lokaci guda, narkakkar kayan yana busa ta hanyar iskar coaxial mai saurin gudu tare da katako don yanke kayan aikin.

Features: High sabon gudun, santsi da kyau surface, daya-lokaci aiki, kananan workpiece nakasawa, babu kayan aiki lalacewa, low tsaftacewa gurbatawa, iya aiwatar da karfe, wadanda ba karfe da kuma wadanda ba karfe hada kayan, fata, itace, fiber, da dai sauransu, dace da mota jiki kauri lafiya yankan shãfe haske na'urorin kamar alluna, auto sassa, lithium batura, pacemakers, daban-daban shãfe haske na'urorin da cewa ba da damar pollution na'urorin, da sauransu

Laser Laser

Ƙa'ida: Yi amfani da Laser mai ƙarfi mai ƙarfi don ba da haske a cikin gida don ƙyale kayan da ke saman ko haifar da canjin sinadarai na canjin launi, don haka barin alamar dindindin.

Fasaloli: Ba aikin sadarwa ba ne kuma ana iya yin alama akan kowace ƙasa mai siffa ta musamman. Aikin aikin ba zai gurɓata ba kuma ya haifar da damuwa na ciki. Yana da babban daidaiton aiki, saurin sarrafa sauri, tsabta da muhalli, ƙarancin farashi, dacewa da ƙarfe, filastik, gilashi, yumbu, da itace. , Fata da sauran kayan.

Walkar Laser

Ƙa'ida: Yi amfani da hasken wutar lantarki mai ƙarfi-yawan Laser don dumama saman kayan aikin, kuma zafin saman yana bazuwa cikin ciki ta hanyar tafiyar da zafi. Ta hanyar sarrafa faɗin, kuzari, ƙarfin kololuwa da maimaitawar bugun bugun laser, kayan aikin yana narke don samar da takamaiman narkakken tafkin.

Features: Weldability an rage, ba shafi Magnetic filayen, kananan sarari ƙuntatawa, babu electrode gurbatawa, dace da atomatik high-gudun waldi, iya weld karafa na daban-daban kaddarorin, iya aiki a cikin kewaye sarari, dace da madauwari saw ruwan wukake, acrylic, spring gaskets, jan faranti na lantarki sassa, wasu karfe raga faranti, baƙin ƙarfe faranti, baƙin ƙarfe, broth Allunan, Bakin karfe Allunan. Gilashin ma'adini, rubber silicon, zanen yumbu na alumina a ƙasa 1mm, titanium gami da ake amfani da su a masana'antar sararin samaniya, da dai sauransu.

Laser Engraving

Ƙa'ida: Laser yana haskaka saman kayan, kuma kayan nan take narke ko vaporizes bayan shayar da makamashi, samar da layin marubuci.

Features: Ƙimar lamba ta atomatik, ƙananan yankin da ke fama da zafi, layi mai kyau, tsaftacewa da juriya na abrasion, kare muhalli da ceton makamashi, kayan ceto, ana iya amfani da su don kayan itace, plexiglass, farantin karfe, gilashi, dutse, crystal, takarda, 2-launi allon, alumina , Fata, resin da sauran kayan etching.

Laser Surface Jiyya - Ana Share Laser

Ka'ida: Yi amfani da Laser don zafi saman kayan don cimma tsaftacewa.

Features: High machining gudun, kananan sassa nakasawa, daidai aiki, atomatik quenching jiyya sakamako, dace da tsatsa kau, shafi kau, Paint tsiri, mai tsaftacewa, kuma mafi aikace-aikace.

3D Bugawa Laser

Ƙa'ida: Ana amfani da foda mai shimfiɗa abin nadi don yada wani Layer na foda a saman kayan aikin, kuma katako na Laser yana duba launi na foda bisa ga ɓangaren kwane-kwane na Layer na foda, don haka foda ya narke da kuma sintered don gane haɗin gwiwar aikin.

Siffofin: Fasaha mai sauƙi mai sauƙi, kayan aiki masu yawa waɗanda za'a iya sarrafa su, babban daidaiton aiki, babu tsarin tallafi, ƙimar amfani da kayan aiki mai girma, haɗe tare da fasahar sarrafa lambobi na kwamfuta da fasahar masana'anta mai sassauƙa, ana iya amfani da su don ƙirar ƙira da ƙirar ƙira.

Ci gaban Laser Micromachining Applications

A halin yanzu, rabon Laser na fiber na kasuwa ya fi na na'urorin da ke da ƙarfi. Babban dalili shi ne cewa ana amfani da Laser na fiber don sarrafa macro mai ƙarfi, kuma buƙatar kasuwa ta dace da matakin haɓaka masana'antar masana'antu; Ana amfani da na'urori masu ƙarfi na Laser don micromachining na Laser, kodayake kasuwar micromachining Laser tana cikin saurin ci gaba. Koyaya, ƙarfin kasuwa na yanzu ya fi ƙarfin kasuwar micromachining, amma masana'anta masu inganci kamar na'urori masu sawa, kwakwalwan kwamfuta, kula da lafiya, da sabon makamashi har yanzu suna buƙatar dogaro da micromachining na laser.

Kodayake nau'ikan injunan Laser daban-daban suna mayar da hankali kan aikace-aikacen masana'antu daban-daban, kuma buƙatun kasuwa don aikace-aikacen ƙasa ya bambanta sosai, akwai wasu bambance-bambance a ma'aunin kasuwar su. Koyaya, yayin da kasuwar injin Laser masana'antu ke ci gaba da haɓaka, aikace-aikacen micromachining Laser a cikin masana'antu da sassan mabukaci zai ci gaba da ƙaruwa a nan gaba.